Laser Cutting Machines, Laser Engraving Machines

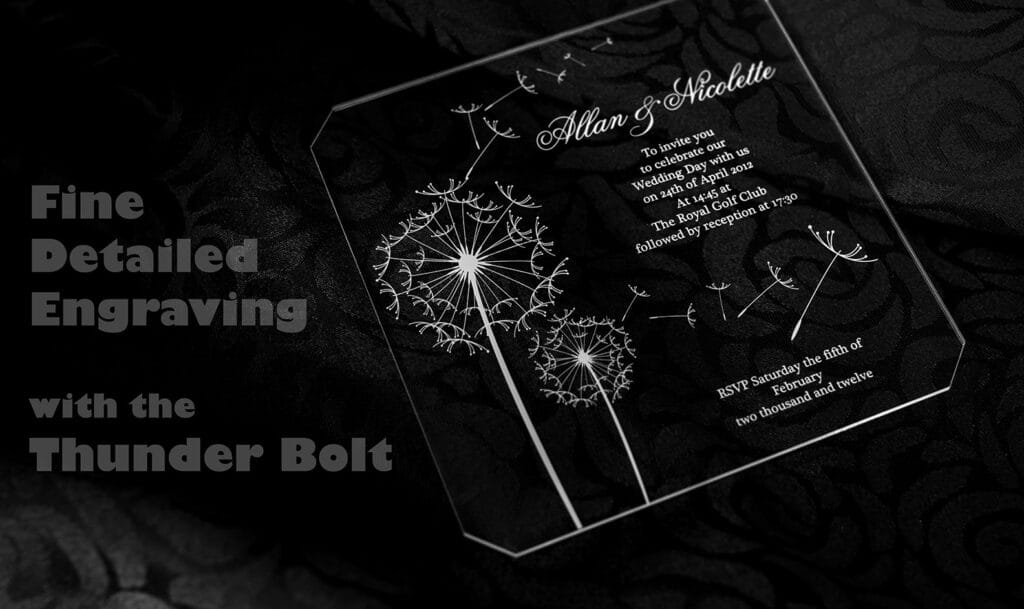

Laser Engraving & Cutting Acrylic

Laser engraving technology has transformed the way we etch detailed and precise designs onto a variety of materials. At its core, this technology employs a high-powered beam to carve patterns and text into surfaces, providing exceptional accuracy and consistency. This is crucial for both artistic expressions and industrial applications. Over the years, I’ve observed small and large businesses reap substantial benefits from incorporating laser engraving machines into their operations, each tailoring their machine choices to suit their specific needs.

Acrylic, in particular, stands out as a versatile material for laser engraving. Known for its durability, clarity, and flexibility, acrylic is an ideal medium for laser work. It can be precisely cut and engraved without compromising its aesthetic appeal, making it a favorite across various industries—from retail signage to custom art pieces. The adaptability of acrylic allows businesses to explore an extensive range of products and services, providing the opportunity to expand their creative boundaries and efficiently meet diverse customer needs.

Through my consultations, I’ve assisted numerous businesses in selecting the appropriate laser engraving machines, witnessing firsthand how the right tools can unlock remarkable creativity and foster business growth.

Understanding Laser Wattage and Acrylic Engraving

Overview of Laser Wattage

In laser machines, wattage refers to the power output of the laser source, which is a critical factor in determining how the machine performs during the engraving and cutting processes. Essentially, the wattage dictates the intensity of the laser beam. Higher wattage lasers can generate more powerful beams, leading to faster cutting and engraving speeds. This can be particularly beneficial when working with thicker materials or when precision is less critical than speed.

However, when it comes to engraving, especially on materials like acrylic, the wattage needs to be carefully considered. Acrylic can be sensitive to excessive heat, which means that too high a wattage could potentially melt or burn the material, rather than achieving a clean engrave. For fine, detailed work on acrylic, a lower wattage can provide a finer beam, offering more control and precision. This is crucial for creating intricate designs without damaging the material’s surface.

In practice, the choice of wattage will largely depend on the specific requirements of the project. For example, engraving fine lines and detailed patterns on thin acrylic might best be accomplished with a laser of around 30 to 60 watts, whereas cutting through thicker sheets of acrylic might require 80 watts or more to achieve clean, efficient cuts. Understanding these nuances allows businesses to optimize their operations for quality, speed, and material conservation, ensuring the best outcomes for every project.

Applications by Watt Size

Choosing the right wattage for your laser engraver is pivotal in tailoring the machine’s capabilities to the specific demands of your projects. Here’s how different wattages align with various engraving and cutting needs:

- Low Watt Lasers (30-60 watts)

- Suitable Projects: Ideal for fine detailing and working with thin acrylic sheets, which are common in crafting personalized items such as jewelry, small signs, and intricate art pieces.

- Benefits:

- Precision: Lower wattage lasers offer superior control over the beam, allowing for precise cuts and engravings that preserve the quality and detail of the design.

- Quality Finish: They minimize the risk of overheating, which can distort the acrylic, ensuring that each piece retains a polished look.

- High Watt Lasers (80 watts and above)

- Suitable Projects: Best for handling thick acrylic sheets and managing large volume orders efficiently. These are typically used in creating larger signs, functional parts for machinery, or decorative panels for architectural uses.

- Benefits:

- Speed: Higher wattage lasers cut and engrave at faster rates, reducing project completion times and enabling businesses to fulfill more orders.

- Efficiency: They can penetrate thicker materials in fewer passes, saving energy and reducing wear on the machine.

- Versatility: Capable of adapting to a range of materials and thicknesses, these lasers can tackle everything from heavy-duty industrial parts to delicate decorative details.

By selecting a laser with the appropriate wattage, businesses can optimize their production processes, enhance the quality of their products, and expand their service offerings to meet broader market needs. This strategic alignment of tool capabilities with project requirements is essential for maximizing efficiency and achieving consistent, high-quality results.

Types of Laser Tubes

Glass Laser Tubes

Glass laser tubes are commonly used in entry-level laser engraving and cutting machines. These tubes are typically made from borosilicate glass and are filled with a gas mixture that includes carbon dioxide, nitrogen, hydrogen, and helium. The technical specifications for glass tubes usually range in power from 30 watts up to about 150 watts, making them suitable for a variety of light commercial and hobbyist applications.

- Pros:

- Cost-effective: Glass tubes are significantly less expensive than their metal tube counterparts, making them an attractive option for beginners or those with limited budgets.

- Sufficient for Small Projects: They are quite adequate for small-scale projects that require moderate precision and are not material-intensive.

- Cons:

- Shorter Lifespan: Typically, glass tubes have a lifespan of around 2 to 3 years, which means they might need to be replaced more frequently depending on usage.

- Less Consistency: The quality of the laser output can vary, leading to inconsistencies in cutting or engraving quality over time.

Metal Laser Tubes

Metal laser tubes, often made from sealed metal or ceramic, are designed for higher-end laser engravers and cutters. These tubes generally start at around 30 watts and can go up to 100 watts or more. They utilize a similar gas mixture as glass tubes but are engineered for more rigorous and continuous use.

- Pros:

- Longer Lifespan: Metal tubes can last between 3 to 6 years, significantly outperforming glass tubes in terms of durability and service life.

- Better Power Stability and Efficiency: They provide a more stable and consistent laser output, which translates into cleaner cuts and engravings, and improved overall machine performance.

- Cons:

- Higher Initial Investment: The upfront cost for metal tubes is considerably higher, which can be a barrier for small businesses or individual operators.

- Maintenance Costs: While generally low maintenance, any required repairs or eventual replacement can be more expensive than with glass tubes.

Both types of laser tubes have their specific niches within the laser engraving and cutting industry. Choosing between a glass and a metal tube will largely depend on your project needs, budget considerations, and expected volume of use, allowing you to balance initial costs against long-term benefits and performance requirements.

Business Ideas Involving Laser Engraving Acrylic

Business Ideas for Smaller Watt Lasers

For entrepreneurs and small businesses, smaller watt lasers provide a cost-effective entry point into the world of laser engraving. These machines are perfect for projects that demand high levels of detail and precision on a smaller scale. Here are some potential business ventures that can thrive with smaller watt lasers:

- Custom Gifts: There is a high demand for personalized gifts such as engraved photo frames, personalized keychains, and custom-designed coasters. These items require precision and care, which smaller watt lasers can provide, making them ideal for businesses focusing on personalized products.

- Small-Scale Decor: Create intricate designs on acrylic for home decor items like wall art, tabletop decorations, and lighting fixtures. These products can be highly customized and are popular in niche markets and boutique stores.

- Personalized Gadgets and Accessories: From smartphone cases to laptop covers, small watt lasers can be used to etch unique designs and text onto various gadgets and accessories, offering customers bespoke products that stand out.

Business Ideas for Larger Watt Lasers

Larger watt lasers expand the range of business opportunities due to their ability to handle bigger projects and cut through thicker materials efficiently. These capabilities open up markets that require larger scale production and heavier materials:

- Industrial Part Production: There is a significant market for custom-cut parts used in various industries. These can range from machinery components to durable tags for equipment. Larger watt lasers can handle the demands of cutting thick acrylic used in these applications, ensuring strength and durability of the parts.

- Large Format Signage: Businesses often need large, eye-catching signs that can withstand the elements and attract customers from a distance. Larger watt lasers can efficiently produce big, bold signage for commercial use, from shop fronts to directional signs in large facilities.

- Construction and Architectural Model Making: Building accurate scale models of buildings and other structures is crucial for architects and construction companies. Larger watt lasers can cut precise and detailed components needed to assemble complex, detailed architectural models.

Whether aiming to start a small, personalized gift business or a larger-scale industrial production company, the type of laser and its wattage play crucial roles in determining what products can be made. Matching the right laser with the right business idea not only maximizes productivity but also enhances the quality of the final product, paving the way for business success in the competitive market of laser engraved goods.

Setting Up Your Laser Engraving Business

Initial Setup

Starting a laser engraving business involves several key steps to ensure you are equipped to deliver high-quality products efficiently and safely. From my experience working with various businesses, the first crucial step is choosing the right laser engraving machine. This choice should be based on the specific types of projects you plan to undertake, considering factors such as the power requirements for different materials and the size of the items you intend to produce.

Once the appropriate machine is selected, preparing your workspace is the next critical step. A well-organized, safe, and efficient workspace is vital for smooth operations. This includes ensuring adequate ventilation to avoid any fumes from acrylic engraving affecting your health, as well as sufficient lighting and space for easy movement around the machine.

Investments don’t stop at the machine; the right software is essential for creating precise designs and effectively running your laser engraver. Additionally, stocking up on high-quality materials for engraving and investing in training can significantly affect the quality of your products and the efficiency of your production process. Proper training not only helps in operating the machine safely but also maximizes its potential by understanding all its capabilities and maintenance needs.

Marketing Your Business

Having set up the technical side of your business, marketing your laser engraving services effectively is crucial to attract and retain customers. One effective strategy I’ve seen is reaching out to potential markets through targeted online marketing campaigns that showcase the unique qualities of laser-engraved products. Building a professional website that highlights your services, portfolio, and customer testimonials can significantly enhance your visibility and credibility.

Moreover, maintaining a strong online presence across social media platforms can help capture a broader audience. Regular posts featuring your latest projects, behind-the-scenes processes, and promotional offers keep the audience engaged and help in building a community around your brand.

Local networking shouldn’t be underestimated either. Participating in local trade shows, community events, and business fairs can introduce your business to local retailers and customers. Building relationships with local businesses that might benefit from customized laser-engraved products, such as event planners, interior designers, and corporate entities, can open up numerous opportunities for projects and collaborations.

From the machines and materials to marketing and community building, setting up a laser engraving business is a multifaceted endeavor. Drawing from my experience helping others set up their operations, focusing on both the technical setup and robust marketing strategies can lay a strong foundation for a successful business.

Conclusion

Laser engraving is more than just a method—it’s a dynamic business opportunity that blends creativity with technology. The versatility of acrylic as a medium further enhances this potential, offering countless possibilities for innovation and customization. From detailed artistic projects to large-scale industrial applications, the scope is vast and varied.

Drawing from my experiences in helping businesses integrate laser engraving into their operations, I’ve witnessed firsthand the transformative impact this technology can have. Whether it’s a small startup focused on bespoke gifts or a larger enterprise producing industrial parts, the right laser setup can lead to substantial growth and success.

By carefully selecting the appropriate laser equipment, setting up an efficient workspace, and implementing strategic marketing efforts, entrepreneurs can not only meet but exceed the expectations of their clients, standing out in a competitive market. As we continue to see advancements in laser technology and materials like acrylic, the future for laser engraving businesses looks bright, promising further innovations and opportunities for creative and commercial applications alike.